Capsuling Machines & Wirehooding Machinery

Automatic capsuling and wirehooding machines

Specialised in “secondary sealing” of all types of bottles and products, we supply wine-producing companies all over the world, as well as cider producers, breweries, distilleries, oil mills and vinegar producers.

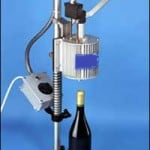

Manual PVC capsuling machine

Manual Tin capsuling machine

This bench hand-operated rolling head is for rolling the multi R-, Al – and tinfoil capsules. Ready for the installation of the capsule-prepolishing piece of equipment for ½ litre to 2 litre bottles having a height from 180 mm. Min. to 360 mm. Max. Bronze rolling spindle with adjustable rolling pressure. Capsule max length 60 mm. Voltage 220/380 V, Hz.50, Kw. 0,18 Speed 1400 rpm (2800 rpm on request) Weight 28 Kg.

We can supply you with all your requirements for capsuling machines. From simple table top capsule shrinking machines to stand alone fully automatic capsuling machines.

Below is a photo of a combi unit with 3 station labelling, combined with a capsuling top sealing machine operating at 2,000 bottles per hour.

"I have absolutely no qualms in recommending IC Filling Systems as a good and reputable company to deal with."

- Jim Quigley, Bottling Manager, Inver House Distillers.

“IC Filling Systems provided our first bottle line that never let us down despite the incredible work load it was asked to perform. As more equipment arrives to further reinforce and advance not just the Mk2 bottle line but the business as a whole, IC Filling Systems will remain our partner of choice. Reliable, consistent and robust.”

- Iain Kerr, Wolfburn Distillery

![]()

"IC Filling Systems installed a new 7,000bph 20-20-5 Neck Handling PET Filler which we are extremely satisfied with. We were provided with excellent customer support from start to finish as well as being provided with a dedicated project engineer to assist with the whole process. Thanks to all the team at IC Filling Systems."

"Purchased a beer filter, 2 head keg filler and 551 bottle filler. We have received great support and our machines are running very well."

- Eben Uys, The Mad Brew Master, Mad Giant, South Africa

"We have worked with a whole host of people since we started in 2017, and by far, the best people we have worked with during that time was Forysths, and I never thought we would work with someone that matched them, but IC Filling Systems did, and in particular, Alessandro was a joy to work with, he was brilliant!! So good to learn from and a great teacher. He is an asset to the company! We would definitely recommend IC Filling Systems to whoever might ask."

- Michael Morrison, Managing Director, Isle of Barra Distillers

Checking...

Retry »

Sending message...

Send us your enquiry today...

Tell us what you need, and we'll respond promptly.

For detailed information

Contact our Sales Director Marco Solferini by calling

+39 0141 162 0091 or +39 0141 74166 (Italy)

+44 1865 520 083 (UK)

Alternatively request

a quotation

Can’t find what you’re looking for?

Search this site...