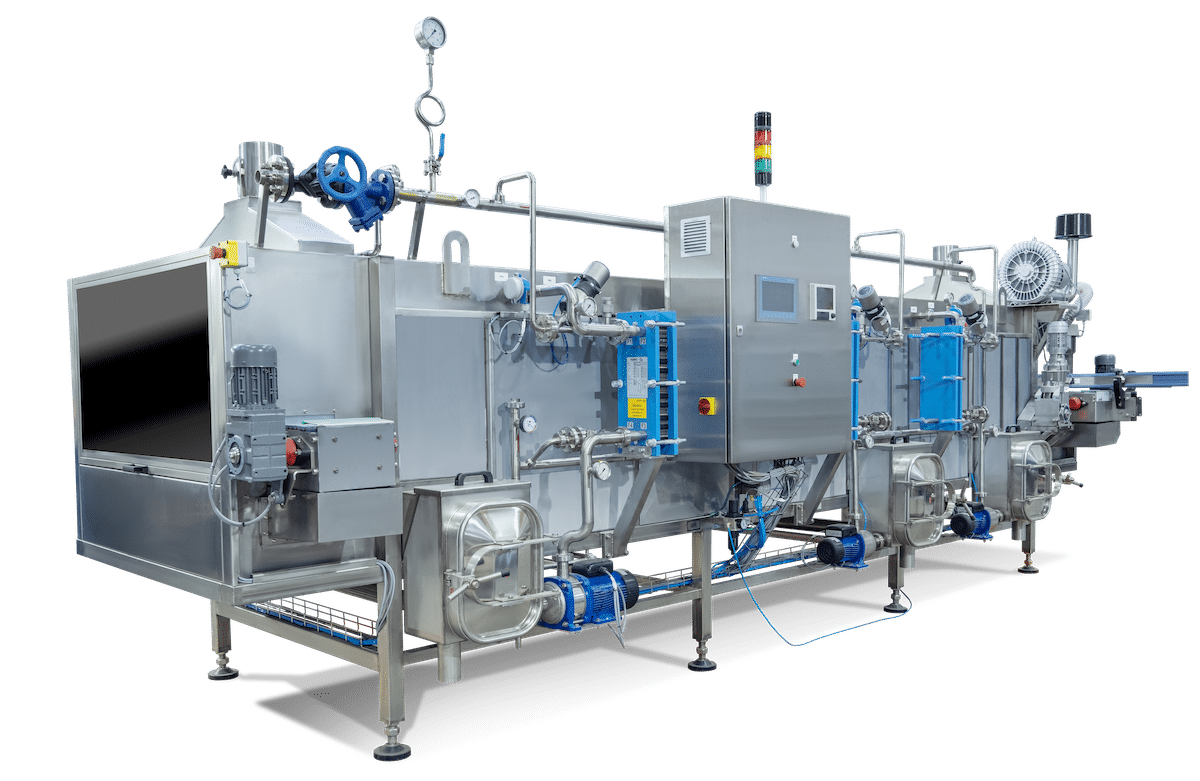

In-Bottle Pasteurisers, Can Tunnel Pasteurisers and Flash Pasteurisers

IC Filling Systems are suppliers of batch or continuous conveyor belt tunnel pasteurisers.

Our models are designed with the highest quality components for the best in sanitary design, ease of maintenance, low operating and maintenance costs, and can process glass bottles or metal cans.

Our pasteurisers convey the product through a controlled temperature environment using an external drive system. Heat transfer is achieved through water sprays delivered over the product by spray headers spanning the width of the pasteuriser.

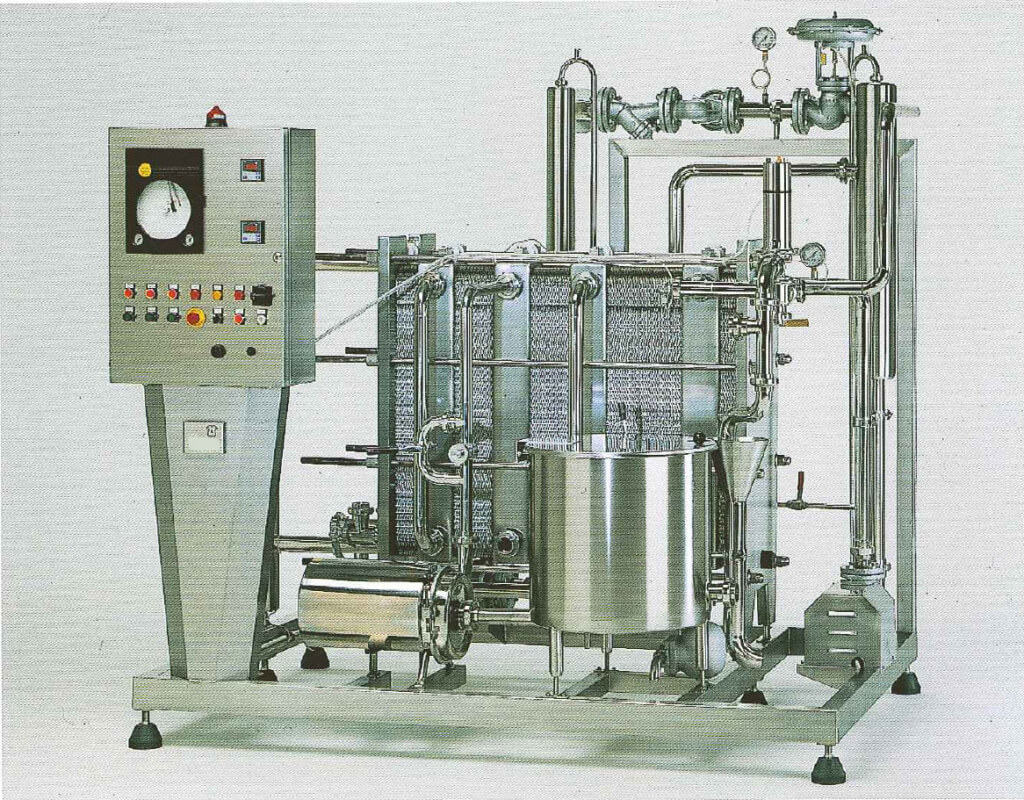

- IC Filling Systems also supply flash pasteurisers for beer and fruit juices.

Small Immersion Batch pasteuriser capable of approximately 100 x 750 ml bottles per cycle

Both single phase in-bottle pasteuriser:

- Capacity: up to 100 (750ml bottles) , 150 x 500 ml 200 x 330 ml

- Dimensions: Width 1250 x Depth 690 x Height 480 mm

- Internal Dimensions: Width 1000 x Depth 640 x Height 345 mm

Single phase in-bottle pasteuriser

- Three immersion heaters, total 9kW

- Tight temperature control

- Integrated time and temperature controller

- Audible and visible alarm

- Optional trolley with lockable wheels

Bottle baskets allow you to increase the throughput of your pasteuriser. Unloading and reloading a basket while a batch is being treated reduces the changeover time between batches, allowing you to increase throughput by around 10%.

Stainless steel bottle baskets are made from strong weld mesh with a reinforced frame and lifting lugs. There are various ways that the baskets can be lifted: with an overhead gantry and hoist, with a fork lift or with a simple engine hoist

Large Immersion Batch pasteuriser capable of approximately 1,000 x 500ml bottles per cycle

"I have absolutely no qualms in recommending IC Filling Systems as a good and reputable company to deal with."

- Jim Quigley, Bottling Manager, Inver House Distillers.

“IC Filling Systems provided our first bottle line that never let us down despite the incredible work load it was asked to perform. As more equipment arrives to further reinforce and advance not just the Mk2 bottle line but the business as a whole, IC Filling Systems will remain our partner of choice. Reliable, consistent and robust.”

- Iain Kerr, Wolfburn Distillery

![]()

"IC Filling Systems installed a new 7,000bph 20-20-5 Neck Handling PET Filler which we are extremely satisfied with. We were provided with excellent customer support from start to finish as well as being provided with a dedicated project engineer to assist with the whole process. Thanks to all the team at IC Filling Systems."

"Purchased a beer filter, 2 head keg filler and 551 bottle filler. We have received great support and our machines are running very well."

- Eben Uys, The Mad Brew Master, Mad Giant, South Africa

"We have worked with a whole host of people since we started in 2017, and by far, the best people we have worked with during that time was Forysths, and I never thought we would work with someone that matched them, but IC Filling Systems did, and in particular, Alessandro was a joy to work with, he was brilliant!! So good to learn from and a great teacher. He is an asset to the company! We would definitely recommend IC Filling Systems to whoever might ask."

- Michael Morrison, Managing Director, Isle of Barra Distillers

Checking...

Retry »

Sending message...

Send us your enquiry today...

Tell us what you need, and we'll respond promptly.

For detailed information

Contact our Sales Director Marco Solferini by calling

+39 0141 162 0091 or +39 0141 74166 (Italy)

+44 1865 520 083 (UK)

Alternatively request

a quotation

Can’t find what you’re looking for?

Search this site...