CAN FILLING: Can filling and seaming add-on kit is now available for the 662 Compactblock

IC Filling Systems globally distributes a wide range of efficient manual filling machines that have been designed to package all types of carbonated beverages (beer, cider, water, soft drinks, kombucha, wine) in glass bottles and close them with crown corks. (Options to fill PET and cans)

Our semi automatic counter-pressure bottling machines are designed specially for the artisan craft brewer or microbrewery to allow economical in-house bottling, with options for conveyors to include labelling and to speed up end of line packaging.

We can supply 2, 4 & 6 bottle rinsers & fillers with single or twin head capping units.

New improved rinser filler crowner compactblock

Improvements driven by you

What our customers asked for and what we delivered...

Hugely improved design with many new and enhanced features including:

- Faster filling cycle

- Higher quality of vacuum for oxygen retention

- Low Oxygen TPO (Total Pickup of Oxygen)

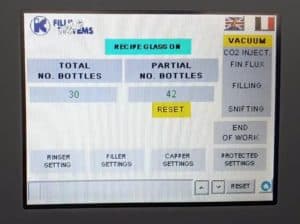

- User friendly HMI touchscreen control panel

- Easy clean stainless steel base with recessed working area

- Total control of filling, pre-evacuation, CO2 flushing and degassing cycle of machine through interactive touch screen

- Ethernet connection available as an option for remote technical diagnosis and assistance

- High visibility vacuum tank to ensure visual monitoring of correct operating status

- Easy visibility and access from rear via transparent opening doors for easy maintenance

- Possibility to fill short neck bottles

- Rinser with "No bottle/can - no spray" system

- Flexibility to fill any size bottle or can

- Easy and rapid changeover from glass bottling to canning

Quick change over for bottles and cans of various heights.

No need for screw adjustments, just click on and click off! Movable pedestals compensate for different heights.

Specifications

- The 6-6-2 compact monoblock (Compactblock) has a production speed up to 500 bottles per hour depending on operator ability and bottle size and configuration of the beer bottling machine

- Bottle sizes possible 370mm height bottles – 150mm diameter bottle

- Caps size: Crown Caps, optional plastic screw caps, ROPP aluminium screw caps and Mushroom corks plus wire hoods.

IC Filling Systems also offer a design and supply service for complete bottling lines including complete bottle or can conveyor systems to connect all individual packaging machines of a complete packaging line to increase production speed and allow all operations to be carried out by a single operator.

CAN FILLING: Can filling and seaming add-on kit is now available for the 6-6-2 Compactblock

Options Available

- Pre-evacuation of air from the bottles (adjustable)

- CO2 flushing of the bottles prior to bottle

- Fobbing of the bottles prior to capping, to cap on foam and remove remaining air in the neck space (used for beer bottling applications)

- Automatic cap sorter for crowns and semi automatic crowning operation. The chute automatically distributes and applies the crown cork as the bottle is inserted into the capping unit.

This type of counterpressure bottling machine can be supplied in 4.4.1, 4.4.2, 6.6.1 or 6.6.2 configurations.

CompactBlock for Carbonated Products

Our 4-4-1 Compactblock combines all phases of bottle filling in a single steel base unit , on wheels for flexible storage when not in operation. Bottle rinsing, Counter-pressure filling and closing with Crown corks.

Ideal bottling equipment for artisan micro-breweries, wineries and small soft drinks producers.

Small Bottling Lines allow small craft brewers to become independent of contract packers, gain flexibility and reduce operating costs. It can also fill Champagne Style mushroom corks, fizzy wines and ciders.

We can deliver a complete production unit including beer and wine carbonators, filtration, storage tanks - just contact us to discuss your precise needs

Canning Option available

Our semi-automatic Compactblock machines can be easily adapted for can filling and seaming.

Isobaric Manual Beer Bottling Machines

Configurations

We also have various configurations counter-pressure fillers & small beer bottling machines

The beer bottling machine comes complete with:

-

- 4 pockets bottle rinser

- 4 isobaric/counter-pressure filling valves diameter 15mm

- 1 head crowner with vibrating sorter

"I have absolutely no qualms in recommending IC Filling Systems as a good and reputable company to deal with."

- Jim Quigley, Bottling Manager, Inver House Distillers.

“IC Filling Systems provided our first bottle line that never let us down despite the incredible work load it was asked to perform. As more equipment arrives to further reinforce and advance not just the Mk2 bottle line but the business as a whole, IC Filling Systems will remain our partner of choice. Reliable, consistent and robust.”

- Iain Kerr, Wolfburn Distillery

![]()

"IC Filling Systems installed a new 7,000bph 20-20-5 Neck Handling PET Filler which we are extremely satisfied with. We were provided with excellent customer support from start to finish as well as being provided with a dedicated project engineer to assist with the whole process. Thanks to all the team at IC Filling Systems."

"Purchased a beer filter, 2 head keg filler and 551 bottle filler. We have received great support and our machines are running very well."

- Eben Uys, The Mad Brew Master, Mad Giant, South Africa

"We have worked with a whole host of people since we started in 2017, and by far, the best people we have worked with during that time was Forysths, and I never thought we would work with someone that matched them, but IC Filling Systems did, and in particular, Alessandro was a joy to work with, he was brilliant!! So good to learn from and a great teacher. He is an asset to the company! We would definitely recommend IC Filling Systems to whoever might ask."

- Michael Morrison, Managing Director, Isle of Barra Distillers

Checking...

Retry »

Sending message...

Send us your enquiry today...

Tell us what you need, and we'll respond promptly.

For detailed information

Contact our Sales Director Marco Solferini by calling

+39 0141 162 0091 or +39 0141 74166 (Italy)

+44 1865 520 083 (UK)

Alternatively request

a quotation

Can’t find what you’re looking for?

Search this site...