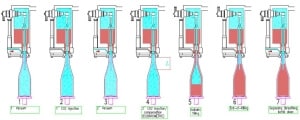

Cleaning in Place (CIP or Clean in Place) is the process of sanitising a filling machine in order to avoid bacteria contamination during production of drinks for human consumption.

The CIP process involves various stages including these main sequences:

- Initial rinsing of the equipment with clean hot water to remove most particles or flavours and sugars.

- Second phase circulating hot water at 80C with a solution of Caustic Soda at 1.5 % or 120C pressurised steam.

- Final hot water rinse.

- Sanitising the machine again with steam at 120C or cold water solution of peracetic disinfectant at 1.5 %

Until recently, closed filling systems were disassembled and cleaned manually. The advent of CIP was a significant time saving technology to industries that needed frequent internal cleaning of their processes.

Industries that rely heavily on CIP are those requiring high levels of hygiene, and include: dairy, beverage, brewing, processed foods, pharmaceutical, and cosmetics.

The benefit to industries that use CIP (Clean in Place) is that the cleaning is faster, less labour-intensive and more repeatable, and poses less of a chemical exposure risk to people.

CIP started as a manual practice involving a balance tank, centrifugal pump, and connection to the system being cleaned. Since the 1950s, CIP has evolved to include fully automated systems with programmable logic controllers, multiple balance tanks, sensors, valves, heat exchangers, data acquisition and specially designed spray nozzle systems. Simple, manually operated CIP systems can still be found in use today.

Depending on soil load and process geometry, the CIP Cleaning-In-Place design principle is one of the following:

- Deliver highly turbulent, high flow-rate solution to effect good cleaning (applies to pipe circuits and some filled equipment).

- Deliver solution as a low-energy spray to fully wet the surface (applies to lightly soiled vessels where a static sprayball may be used).

- Deliver a high energy impinging spray (applies to highly soiled or large diameter vessels where a dynamic spray device may be used).

Elevated temperature and chemical detergents are also employed to enhance cleaning effectiveness.

- CIP Cleaning in Place details of recirculation pipes

- CIP Cleaning in Place control Panel

- 500 litres CIP twin tank unit

- Details of CIP cycle

"I have absolutely no qualms in recommending IC Filling Systems as a good and reputable company to deal with."

- Jim Quigley, Bottling Manager, Inver House Distillers.

“IC Filling Systems provided our first bottle line that never let us down despite the incredible work load it was asked to perform. As more equipment arrives to further reinforce and advance not just the Mk2 bottle line but the business as a whole, IC Filling Systems will remain our partner of choice. Reliable, consistent and robust.”

- Iain Kerr, Wolfburn Distillery

![]()

"IC Filling Systems installed a new 7,000bph 20-20-5 Neck Handling PET Filler which we are extremely satisfied with. We were provided with excellent customer support from start to finish as well as being provided with a dedicated project engineer to assist with the whole process. Thanks to all the team at IC Filling Systems."

"Purchased a beer filter, 2 head keg filler and 551 bottle filler. We have received great support and our machines are running very well."

- Eben Uys, The Mad Brew Master, Mad Giant, South Africa

"We have worked with a whole host of people since we started in 2017, and by far, the best people we have worked with during that time was Forysths, and I never thought we would work with someone that matched them, but IC Filling Systems did, and in particular, Alessandro was a joy to work with, he was brilliant!! So good to learn from and a great teacher. He is an asset to the company! We would definitely recommend IC Filling Systems to whoever might ask."

- Michael Morrison, Managing Director, Isle of Barra Distillers

Checking...

Retry »

Sending message...

Send us your enquiry today...

Tell us what you need, and we'll respond promptly.

For detailed information

Contact our Sales Director Marco Solferini by calling

+39 0141 162 0091 or +39 0141 74166 (Italy)

+44 1865 520 083 (UK)

Alternatively request

a quotation

Can’t find what you’re looking for?

Search this site...