Bottle & Crate Depalletisers

A Bottle or Crate Depalletiser allows automatic unloading and alignment of all kinds of palletised glass, metal and plastic containers.

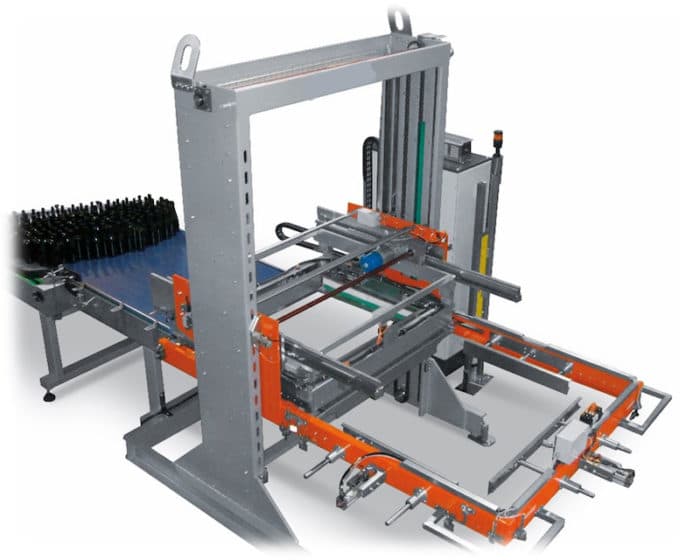

Automatic Sweep-off Depalletiser

Suitable to remove from pallets from a wide variety of containers such as plastic and glass bottles, jars, cans, pots, flasks, etc. Its operation is practical and reliable.

The containers are swept off the pallet layer by a clamp and carriage system and are unloaded onto a conveyor table which feeds the containers inline to the rest of the filling line.

Wide flexibility and great reliability are the main features of this machine.

- Format changeover operations are quick and maintenance is very minimal. All the movements occur thanks to ball bearing with seals or self-lubricating bushes.

- Depalletizer with layer push system, for the processing of bottles, glass jars, tin-plated aluminium cans of cylindrical or rectangular shape. The characteristic of the pallet to be depalletized is to have plastic or rigid cardboard layer pads.

- The machine is fully automated and is a model suitable for bottling lines with production capacities up to 500 containers/minute.

- Machine suitable for frequent format changes, since it does not need any additional equipment and the height parameters of the product are input through its Touchscreen display.

- Machine equipped with independent perimetric centring device controlling the pallet permanently, without releasing it, till exhaustion. The centring system provides to align the rows of the bottles before the gripper head arrives and to wrap the pallet preventing the accidental fall of the bottles.

Equipped with an independent and rotating automated pad and top frame remover, with two separate magazines for the removal in automatic mode of both the top frames from the top of the pallets and the layer pads. The presence of the operator is required only for the removal of the protection wrap in the pallet unwrapping unit.

The working system is with stationary pallet with a self-levelling depalletizing unit, solid support framework with two columns with counterweights. All movements are mechanical, motorized, and controlled through variable speed drive inverters for precise and soft starts and stops.

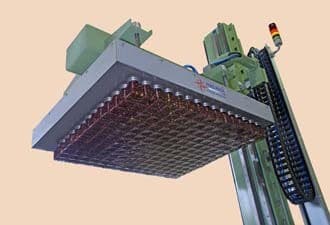

Semi-Automatic Depalletiser

Suitable to satisfy small and medium output requirements (1,000 – 6,000 BPH) and automatically remove bottles, cans, jars and tins from pallets.

Automatic operation, practicality and reliability are the main features of this machine.

Format changeovers are very quick and it needs very little maintenance. The overall dimensions of the machine are very compact.

- Machine suitable for the depalletizing of bottles, glasses, jars, and tins with transfer of one layer at a time through gripping (NECK HANDLING), a system enabling inserting both flat pads and trays between the layers.

- Machine with manual or semiautomatic controls suitable for bottling lines with production capacities up to 150 containers/minute.

- The machine was designed to enable a single operator to feed the line with simple operations, so eliminating al physical efforts.

- The movements are mechanical motorized controlled through variable speed drive inverter for precise and soft starts and stops.

The sturdy framework is open on 3 sides to allow easy access to the operator for rapid adjustment at the format change, without the use of wrenches through suitable spacing templates. The gripping head features inflatable profiles or other gripping systems (hooks, magnetic heads, pincers).

Contact IC Filling Systems…

For detailed information, contact our Sales Director Marco Solferini by calling +39 0141 162 0091 or +39 0141 74166 (Italy) or +44 1865 520 083 (UK). Alternatively, use the contact form below, or request a quotation.Checking...

Retry »

Sending message...

Send us your enquiry today...

Tell us what you need to know, and we'll respond promptly.