Microblock: Automatic, Versatile and Economical for Sparkling Wine

661 Automatic Microblock for Automatic Filling of Sparkling Wine

Flexibility to handle different bottle sizes

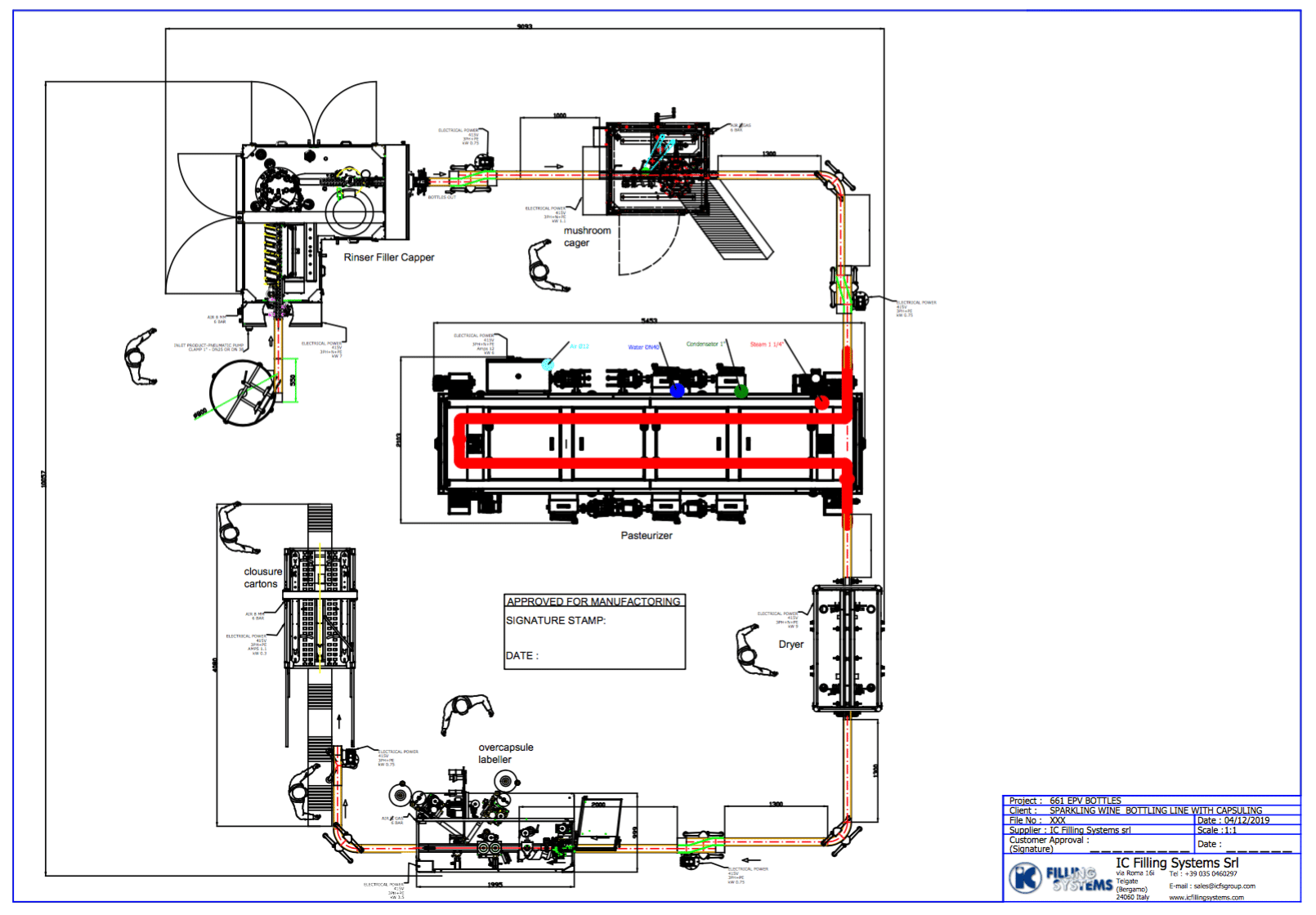

661 EPV counterpressure filling Microblock for Sparkling Wine

IC Filling Systems has produced an improved Automatic rinser-filler-capper suitable for a variety of uses.

This high quality, high tech, automatic 661 bottling machine features new EPV Electro Pneumatic Filling Valves, counter-pressure model for handling carbonated and still beverages.

The 661 EPV can apply both mushroom corks and 30x60mm ROPP metal Stelvin screwcaps, and fill either still or carbonated wines in an oxygen free environment.

High capacity automatic filling controlled by a single operator

The brand new Microblock 661 EPV hosts a number of major improvements on its specifications as it places itself as the innovative new generation system compared to similar all-in-one machines on the market.

- It fills both glass and aluminium cans. Pretty much a first in the industry!

- It assists the filling speed with a new high performance vacuum pump

- It fills any shape of bottle: square, rectangular and oval - not only round bottles

- It can apply ANY type of caps: ROPP, Mushroom Cork, crown corks, and plastic T-corks

- It can handle TWO different style of caps on the same capping turret

- A single high output filling tank ensures constant product filling levels at top speed

- User friendly 7” colour HMI touchscreen control panel & PLC

- Ethernet remote software access available as an option for remote technical diagnosis and assistance

- Integral Brushless electronic cam operations for more accurate positioning of bottles or cans and faster servicing

The 661 EPV filing machine is suitable for filling any still or carbonated product: wine, water, soft drinks, and it features our new EPV (Electro Pneumatic Valve) technology. The EPV valve allows total flexibility in adjusting the filling cycle by adapting the vacuum filling and levels off timings to the necessity of each different drink via a colour touchscreen HMI control panel.

Three independent sections driven by servo motors

Microblock 661 EPV consists of a Linear Rinsing Section supplied with 6 rinsing nozzles, 6 Electro-pneumatic Isobaric Counterpressure filling valves and a single head capping turret suitable for any combination of two different cap application on glass bottles. Special combined cap applications such as ROPP screw cap, Mushroom cork, natural straight cork and plastic screw cap are available on request.

The machine is also equipped with a device to detect the bottle on the conveyor (no bottles on conveyor, no rinse) featuring a photocell which stops the machine and closes the rinser electro valve in case of missing bottles.

The Microblock 661 EPV bottle filling machine is hygienic & easy to clean, made from stainless steel wherever possible.

Contact IC Filling Systems…

For detailed information, contact our Sales Director Marco Solferini by calling +39 0141 162 0091 or +39 0141 74166 (Italy) or +44 1865 520 083 (UK). Alternatively, use the contact form below, or request a quotation.Checking...

Retry »

Sending message...

Send us your enquiry today...

Tell us what you need to know, and we'll respond promptly.