P-System and Tubular Flash Pasteurising Equipment for Aseptic Filling

P-System and Tubular Flash Pasteurising Equipment for Aseptic Filling

Intercaps Filling Systems Ltd is involved in the field of beverages preparation and treatment with a wide range of equipment including water purifying systems, syrup rooms, premix units, CIP units and flash pasteurising units.

This commitment had now been extended till the edges of the currently available technology in the latest version of flash pasteurising equipment for juices aseptic filling, for sure one of the hardest challenges for a process equipment manufacturing company.

Aseptic filling holds a strategic interest for the future of IC Filling Systems because of the currently increasing attention of the rising markets (mainly Africa, Middle East and South America) on aseptic filled beverages: hence the companies’ board decided to invest technical and economical resources on the development of this process.

The tubular flash pasteurising equipment or aseptic filling - is a fully automatic juice flash pasteurizing unit, which allows the inactivation of all those micro-organisms naturally present in the product or introduced during the processing causing the fermentation and the following product spoilage.

The flash pasteurization entirely meets technical and safety requirements and at the same time minimizes any organoleptic alteration of the product by operating with the utmost precision at the temperatures required by the process for a time which is usually in function of the product typology.

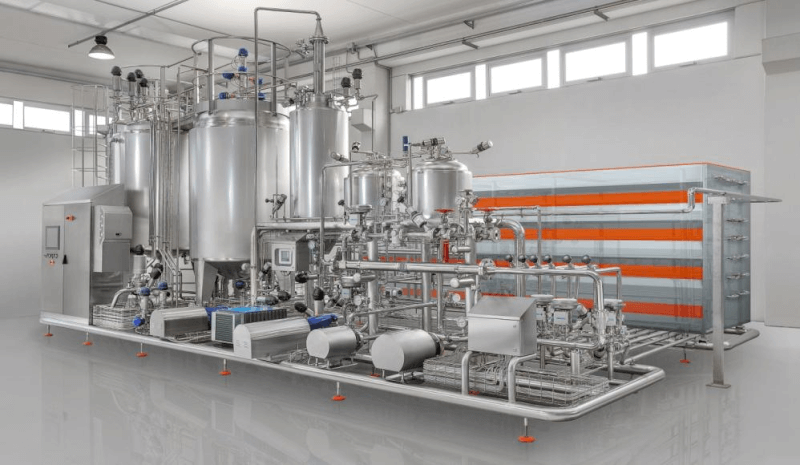

The unit is supplied completely preassembled on a stainless steel circular-section skid for an easy and efficacious cleaning of the external parts too.

All the parts in contact with the product are manufactured in AISI 316 L stainless steel to be highly resistant to the effect of sanitizing agents.

The control panel air conditioning system is provided with NEMA 4X certification for the maximum IP protection. The control panel and the junction boxes are provided with sloping top to avoid dust accumulation.

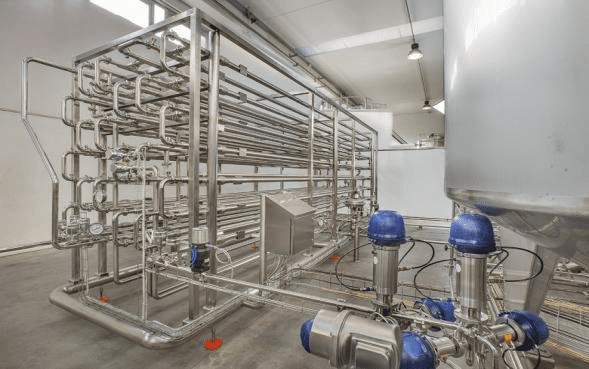

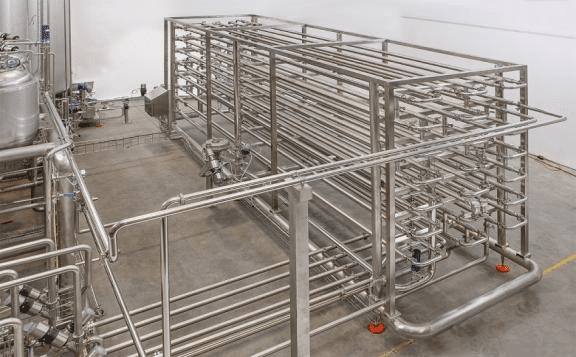

The pasteurizing process is carried out through a 4- sections set of tubular heat exchangers (pre-heating before deaeration, pasteurizing, heat recovery and final cooling); tubular heat exchangers are manufactured in AISI 316 L stainless steel and thermally insulated with a special cover realized in stainless steel and rockwool (the casing in stainless steel prevent the rockwool to get in contact with humidity, chemicals, etc.).

The unit is provided with sanitary design lobes pumps ensuring a gentle treatment of the product even in case of pulps and fruit cells presence.

In case of filler stop the product is stored in an aseptic buffer tank protected by a set of aseptic double chamber valves. The integrated steam barrier of these valves enables the safe separation of both product lines via the two seat seals and the integrated function of the single-seat lifting capability permits fully automatic seat cleaning during production.

The number of seals and moving parts are reduced to a minimum to provide easy maintenance.

The process is fully automatic and controlled by PLC and 19” touchscreen for the best access to process parameters; furthermore the equipment is interfaced with the rest of the line via ETHERNET and with the manufacturer’s factory via web.

Other features of the equipment are a high automation level (including the use of ASi-bus for field control of pneumatic valves) and process control (systems can be equipped with SCADA supervision software), a strong attention to hygienic aspects to avoid any possible contamination of a such delicate product and a strong attention to the reliability of used components.

The choice made by us to use high quality components manufactured by well known international producers fully integrate our daily job philosophy and guarantee the customers an easy way to find the spare parts.

The mechanical preparation of the part to be welded is aimed to reach the maximum hygiene in the piping guaranteeing the complete drain of the plant and the absence of dead ends.