New 6-6-1-1 EPV Microblock for cans and bottles is even more Micro!

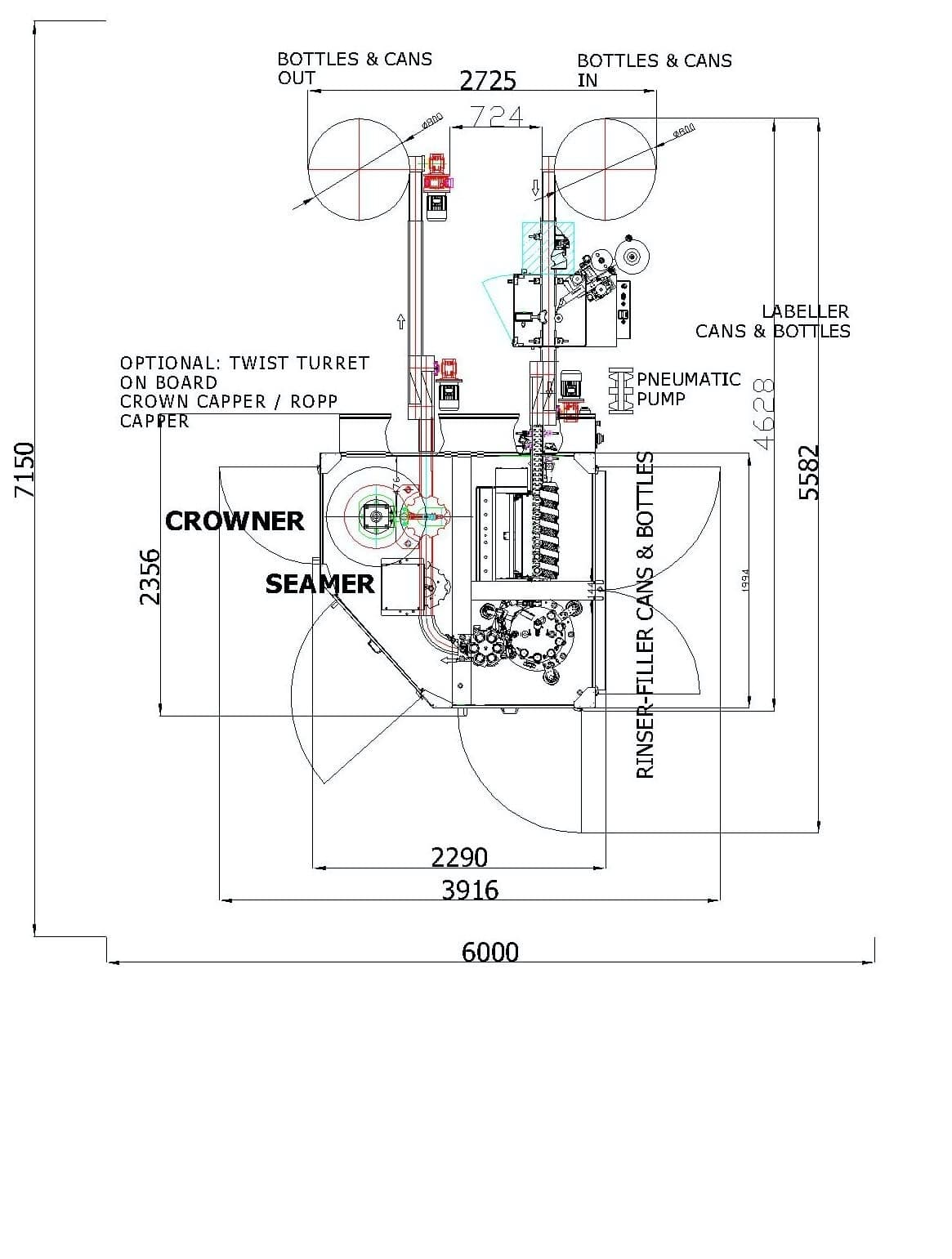

6-6-1-1 Monoblock filling line layout

The new 6-6-1-1 EPV Microblock isobaric Hybrid filler for cans and glass bottles is now even more Micro!

After the success of the 6-6-1 EPV in its glass or can filler version and the latest Hybrid (cans and bottles) version, IC Filling Systems are now launching the integrated version of the Hybrid 661 EPV.

Crown Cap detail

Can seamer detail on 661 EPV

Until now only the can seamer or the crown capper were on board the monoblock, and the second capper was integrated as a stand alone unit separate from the main filler. Now the new Integrated hybrid 6-6-1-1 has both capper and seamer on board the main monoblock unit.

This allows an even smaller footprint of system which is characterised by a U shaped horseshoe configuration. Its compact 6 x 5 metre footprint can fit in a room 7 x 6 metres. This is specially suitable for the limited space normally available at craft drinks manufacturers, brewers and cider producers. The compressed layout includes labelling and loading and unloading rotary tables. Containers are loaded and unloaded from the same side, allowing for just having one operator attending the line!

No other systems of combined cans and glass bottles can fit into such a limited space. This adds this to the other features of the 6-6-1-1 EPV series, namely (a) high speed for an entry-level automatic filling plant, (b) the most competitive price on the market in its class, and (c) the lowest TPO levels thanks to enhanced pre-evacuation of oxygen.

>> See more detailed product page

Contact us today for more information and a quote.